Activated glass filter media (AFM) is a modern, high-performance filtration medium made from recycled glass, designed to replace traditional sand in various filtration systems. It offers enhanced performance and several benefits over conventional filter media.

How it works

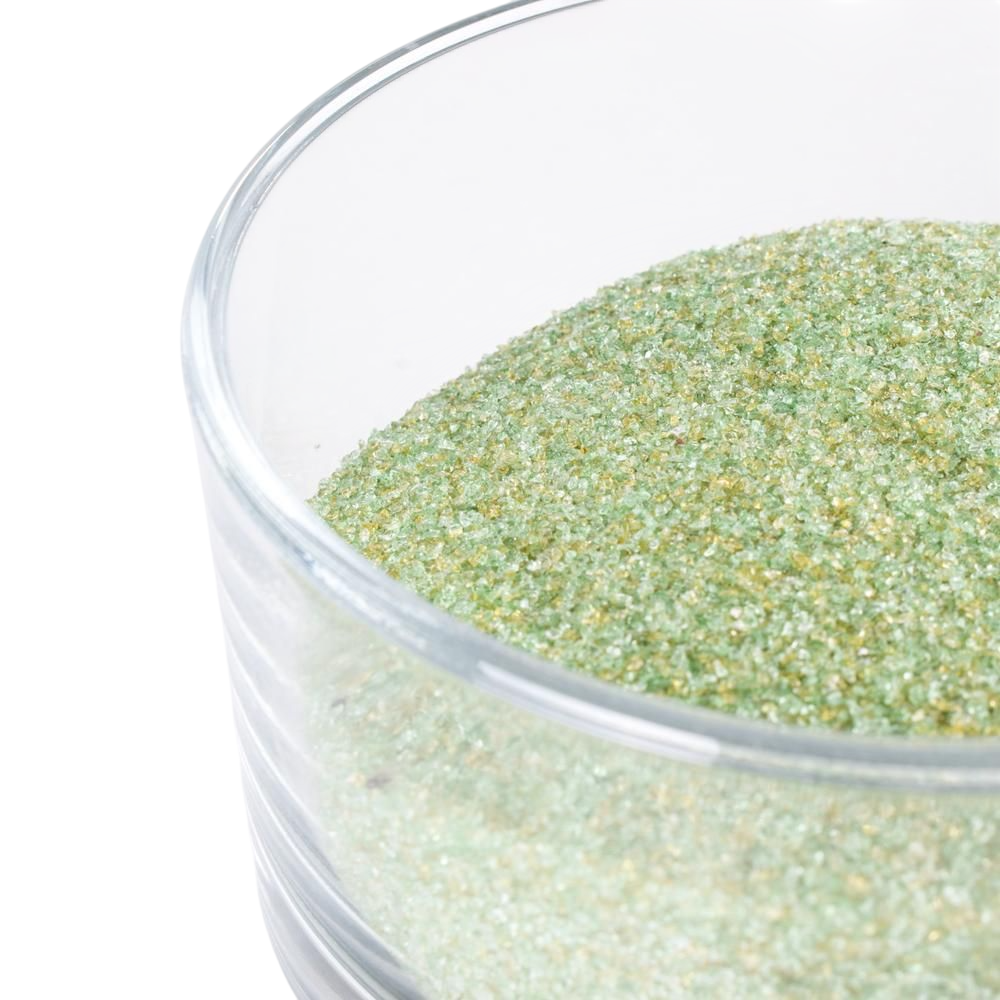

- Material and Processing: AFM is manufactured from specific green and brown glass types that possess certain metal oxides crucial for the activation process. This glass is carefully processed to achieve the optimal particle size and shape.

- Activation Process: The glass undergoes a multi-step activation process that significantly increases its surface area (up to 300 times more than sand) and imparts a negative surface charge (zeta potential). This negatively charged surface enhances the adsorption of positively charged particles, including fine particles, microorganisms, and organic matter. A multi-step activation process, involving physical and chemical treatments, increases the surface area of the glass and creates a unique electrostatic charge.

- Self-Sterilizing Properties: The activated surface of AFM is self-sterilizing due to the presence of metal oxide catalysts that generate free radicals in the presence of oxygen or oxidizing agents. This feature helps prevent the growth of bacteria and the formation of biofilm within the filter bed.

- Filtration and Regeneration: Water flows through the AFM media in a filter vessel, and contaminants are captured through both mechanical filtration and electrostatic adsorption. Periodically, the AFM media is regenerated through backwashing, a process that removes accumulated contaminants and extends the lifespan of the media. It filters down to 1 micron, surpassing the performance of sand and other glass filter media. It requires less backwash water due to its efficient filtration and resistance to clogging.

- Durability: AFM lasts longer than sand, reducing the need for frequent replacements.

- Direct Replacement: AFM can be used as a direct replacement for sand in existing sand filters without needing significant infrastructure changes.

- Reduced Chemical Consumption: By inhibiting biofilm growth, AFM reduces the need for chlorine and other chemicals.

Key advantages of AFM

- Superior Filtration: Filters down to a finer level (as low as 1 micron, compared to 20-30 microns for sand). This results in clearer water quality and improved removal of a wider range of contaminants.

- Bio-Resistance: AFM's self-sterilizing surface prevents the growth of bacteria and the formation of biofilm, reducing the risk of contamination and filter clogging. This also leads to a reduction in chlorine demand, as biofilm buildup often requires higher chlorine doses. This activation makes the media self-sterilizing, preventing the growth of bacteria and biofilm.

- Longer Lifespan: AFM can last significantly longer than traditional sand (up to 15 years or more compared to 3-5 years for sand). This reduces the need for frequent media replacement and associated costs.

- Reduced Maintenance and Operational Costs: AFM requires less frequent backwashing and uses less backwash water (up to 50% less) compared to sand, leading to savings in water, energy, and chemical consumption.

- Environmental Benefits: Made from recycled glass, AFM is an eco-friendly choice that contributes to waste reduction and sustainable water treatment practices.

Applications

AFM is suitable for a wide range of water treatment applications, including:

- Drinking Water Treatment: Removing heavy metals (e.g., iron, manganese, arsenic), turbidity, and organic chemicals.

- Swimming Pool Water Treatment: Maintaining crystal clear water, preventing biofilm growth, and reducing chlorine and chemical usage.

- Wastewater Treatment: Removing suspended solids, organic pollutants, phosphorus, and bacteria.

- Pre-treatment for Membranes (RO/UF): Improving the performance and lifespan of membranes by reducing the silt density index (SDI) of the water.

In conclusion, AFM represents an advanced and sustainable alternative to traditional sand filters, offering superior filtration performance, extended lifespan, and reduced maintenance requirements.