| FIG. | PARTS | MATERIAL |

| 1 | Body | U-PVC |

| 2 | Seat Seal | EPDM & VITON |

| 3 | Disc | U-PVC |

| 4 | O-Ring | EPDM & VITON |

| 5 | Stem/Shaft | SS 304 |

| 6 | Bear | ABS |

| 7 | Plate | U-PVC |

| 8 | Screw | SS |

| 9 | Cap | U-PVC |

| 10 | Bracket Pad | ISO 5211 |

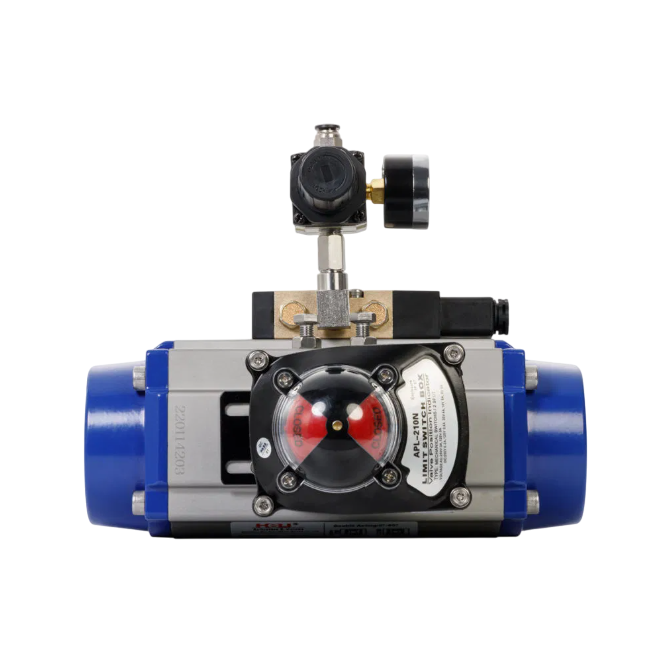

| 11 | Actuator | Standard |

A EVA pneumatic actuated UPVC butterfly valve is a robust and efficient flow control solution used in various industrial and domestic applications. It combines the chemical resistance and lightweight properties of UPVC (unplasticized polyvinyl chloride) with the automatic and precise control offered by a pneumatic actuator.

Here's a breakdown of its key aspects:

What is it?

- Butterfly Valve: A quarter-turn valve that regulates fluid flow by rotating a disc within the pipe. The disc is perpendicular to the flow when closed and parallel when fully open.

- UPVC Construction: The valve body and disc are made from UPVC, a durable, rigid, and non-corrosive plastic material resistant to chemicals, weathering, and UV radiation. This makes it suitable for demanding environments.

- Pneumatic Actuator: This device uses compressed air or gas to generate the force required to open and close the valve. It offers remote operation and automation capabilities.

Key features and advantages : -

- Corrosion resistance: UPVC construction resists acids, alkalis, salts, and many chemicals, ensuring a long service life.

- Automatic operation: The pneumatic actuator allows for remote control and integration into automated systems.

- Precise flow control: Depending on the actuator type, it can be used for on/off control or modulating flow regulation.

- Compact and lightweight design: Makes for easy installation and maintenance.

- Cost-effective: Generally, lower costs for both the valve and actuator compared to alternative materials or actuation methods.

- Low maintenance: Pneumatic actuators have fewer moving parts and require minimal lubrication or servicing.

- Intrinsic safety: Eliminates electrical hazards, making them suitable for hazardous environments.

- Versatility: Can handle a wide range of media including gases, liquids, and semi-solids.

- Long service life: Designed for high-cycle operations with minimal wear.

Applications : -

- Water Treatment: Crucial for controlling water flow in treatment processes.

- Chemical Processing: Handles corrosive and non-corrosive chemicals effectively.

- Industrial Manufacturing: Regulates flow in various industrial processes.

- HVAC Systems: Controls airflow and fluids in heating, ventilation, and air conditioning systems.

- Food and Beverage: Ensures hygienic flow control for liquids and semi-solids.

- Wastewater Treatment: Manages the flow and direction of sewage and effluent.

- Power Generation: Controls the flow of water, steam, and other fluids.

- Mining and Metallurgy: Handles slurries and abrasive materials effectively.

Types of pneumatic actuators : -

- Single-acting (Spring-Return): Uses air pressure for one direction of movement (opening or closing), and a spring returns it to the default position (fail-safe).

- Double-acting: Uses air pressure for both opening and closing actions, providing more precise control.

Choosing the right pneumatic actuator

- Valve type: Ensure compatibility with butterfly valves (rotary motion).

- Torque requirements: Determine the necessary force to operate the valve based on size, pressure, and media.

- Operating conditions: Consider temperature, humidity, and the presence of corrosive substances.

- Air supply: Verify the availability of clean, dry air at the required pressure and volume.

- Control needs: Choose between on/off or modulating control based on the application.

- Safety features: Evaluate fail-safe options (e.g., spring return) for critical applications.

- Cost and lifecycle: Weigh the initial cost against factors like maintenance and energy consumption.

Installation and maintenance

- Proper Alignment: Ensure the valve is correctly positioned and aligned with the piping.

- Secure Installation: Fasten the valve securely using the appropriate bolting method (e.g., wafer, lugged).

- Actuator Connection: Attach the actuator to the valve stem and position it correctly.

- Testing: Verify the valve operates smoothly after installation and before commissioning.

- Regular Inspections: Check for leaks, signs of wear, and actuator function regularly.

- Lubrication: Lubricate the actuator and valve components as recommended by the manufacturer.

By considering these factors and following proper installation and maintenance procedures, pneumatic actuated UPVC butterfly valves can provide reliable and efficient flow control in various demanding applications.

Accessories: -

- On/Off Indicator

- Namur Standard Solenoid Valve in all Standard Coil Voltage (Falme Proof Solenoid Coil – On Request)

- Pneumatic & Electro Pneumatic Valve Positioner

- Declutchable Manual Over Ride

- Limit Switch On/Off indication at Panel Borad

- Filter + Regulator Combination with Pressure Guage

- Air Lock Valve